Efter lång utveckling i många år så är äntligen nya GVW - Wastegate serien lanserad !

Information ifrån Garrett :

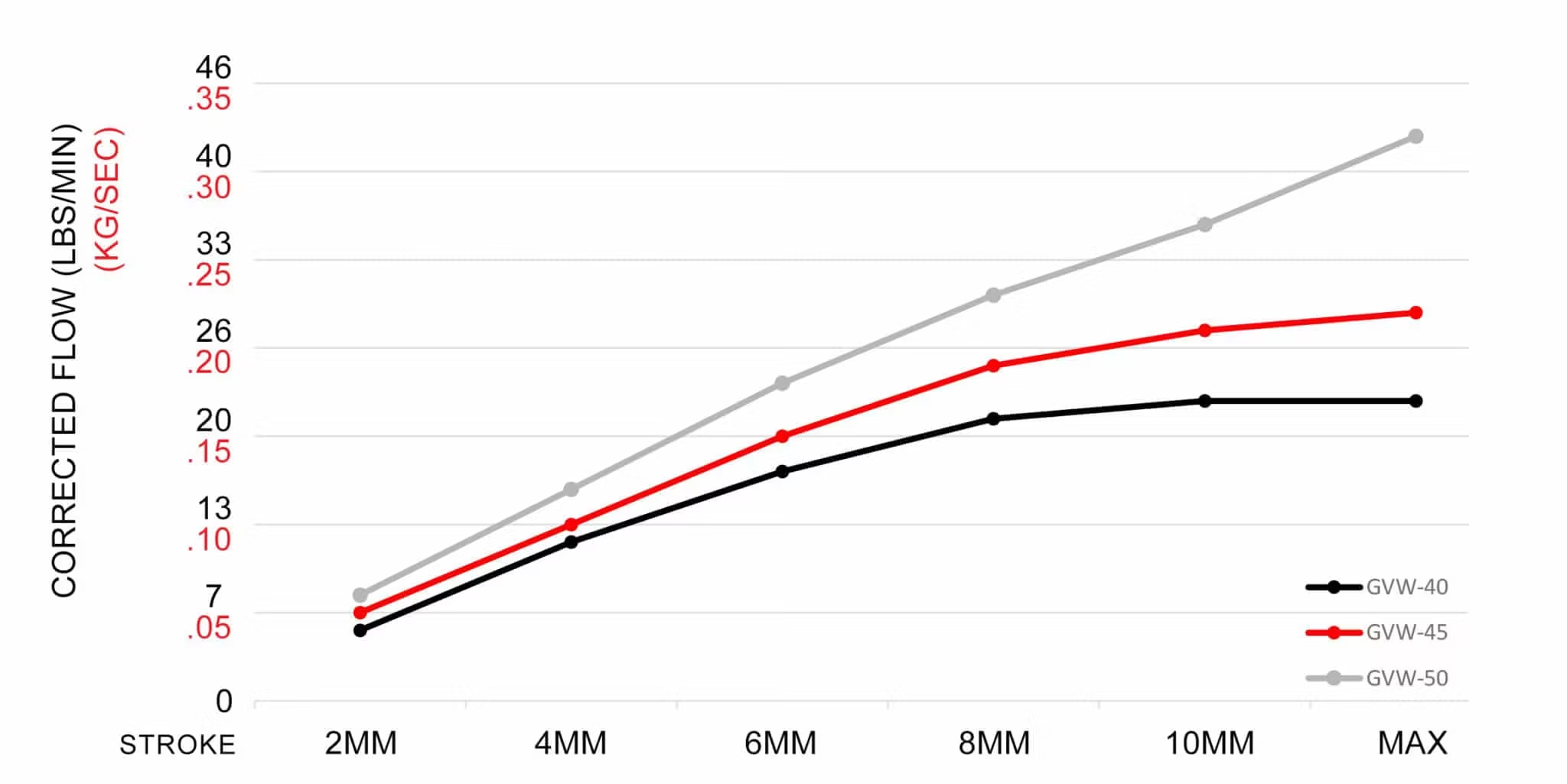

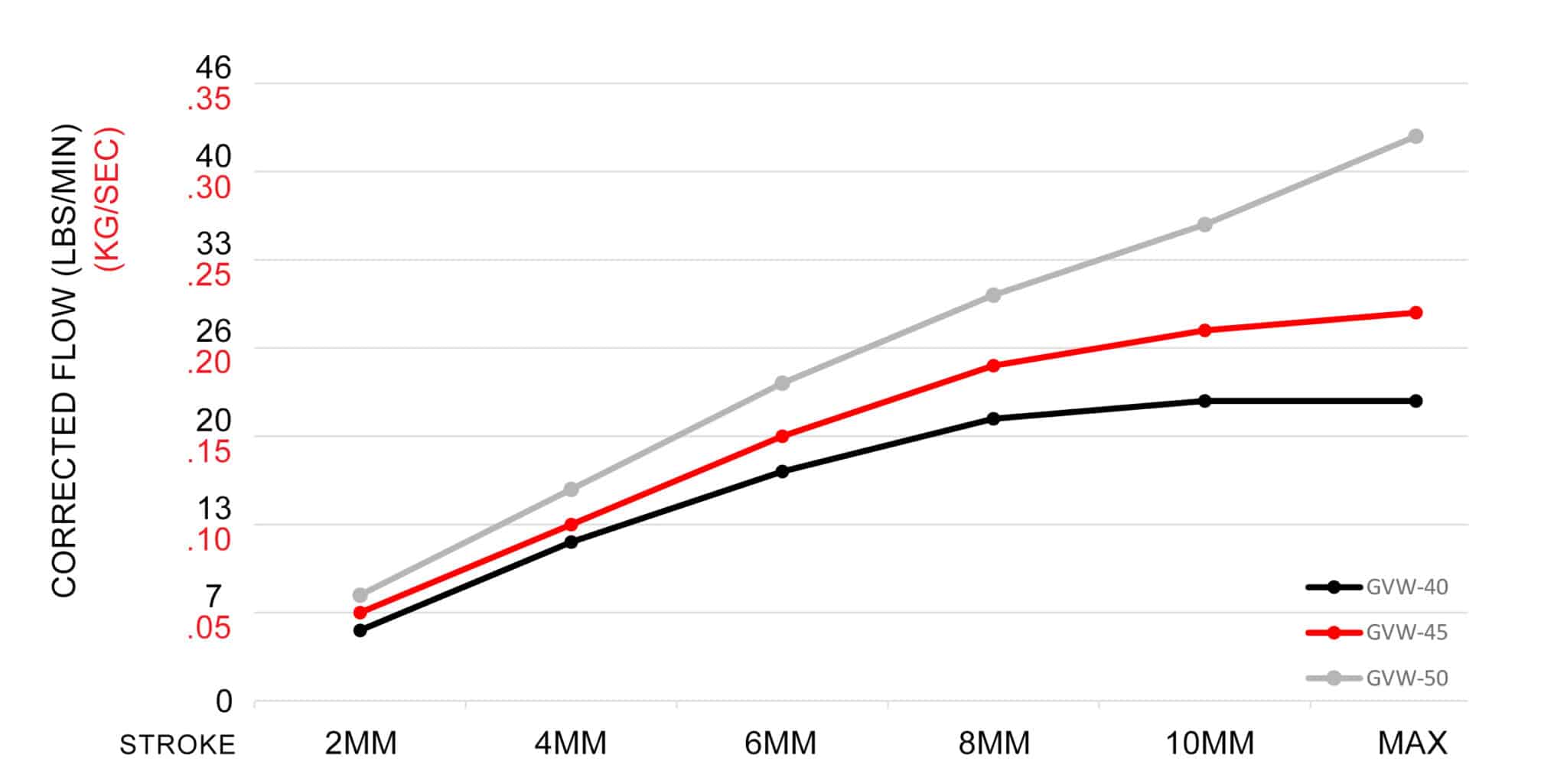

Flow Data

Garrett engineers created GVW as a high flowing product with low degradation in performance over its lifespan. Here’s how the three GVW wastegate sizes flow in LBS/MIN and KG/SEC at various increments of the valve stroke.

Material Data

The valve housing is cast from high temp stainless steel and rated for exhaust temperatures up to 1050° C. CFD optimized for maximum flow and thermal efficiency.

- Valve Housing: High temp stainless steel rated up to 1050° C

- Diaphragm: High temp Nomex reinforced elastomer

- Actuator Cover: Fully-machined anodized 6061 aluminum

- Valve Guide | Bushing: Nitronic 60

- Valve: high temp stainless steel with plated stem

- V-Band: CNC machined 304 stainless steel

- Flanges: Fully-machined 304 stainless steel

- Springs: 17/7 PH stainless steel

Mechanical Data

Garrett Vent | External Wastegates are created by the engineers that designed G-Series and GTX Gen II turbochargers. Available in three sizes: 40mm | 45mm | 50mm

- Valve Diameter: 40mm | 45mm | 50mm

- Valve Mass: (40mm)1.27kg | 45oz (45mm) 1.47kg | 52oz (50mm) 1.56kg | 55oz

- Max Spring Base Pressure: 1.7 bar | 25 psi (1:1 backpressure ratio)

- Minimum Spring Base Pressure: 0.2 bar | 3 psi (1:1 backpressure ratio)

- Port Fitting | Air: M10x1.0 to hose barb (hose ID 6mm | .25in)

- Port Fitting | Water: M8x1.0 to AN-3

Thermal Data

When researching and testing common shortfalls of wastegates, we observed how heat cycling and normal wear can rapidly change their actuation characteristics. Garrett engineers created GVW as a high flowing product with low degradation in performance over its lifespan. Actuation data (opening and closing) in the chart was measured before and after extreme testing conditions. Results show the heat cycled GVW product maintains linear control of the wastegate as compared to the new product. Precise actuation of the GVW provides accurate calibration settings and performance throughout the lifespan of the product. Accurate wastegates, allow for optimum performance of the turbocharger.

- Max Thermal Stress (non-cooled): 270°C actuator body temp during thermal cycle test

- Max Thermal Stress (liquid-cooled): 130°C actuator body temp during thermal cycle test

- Max Exhaust Temp | Peak: Up to 1050°C

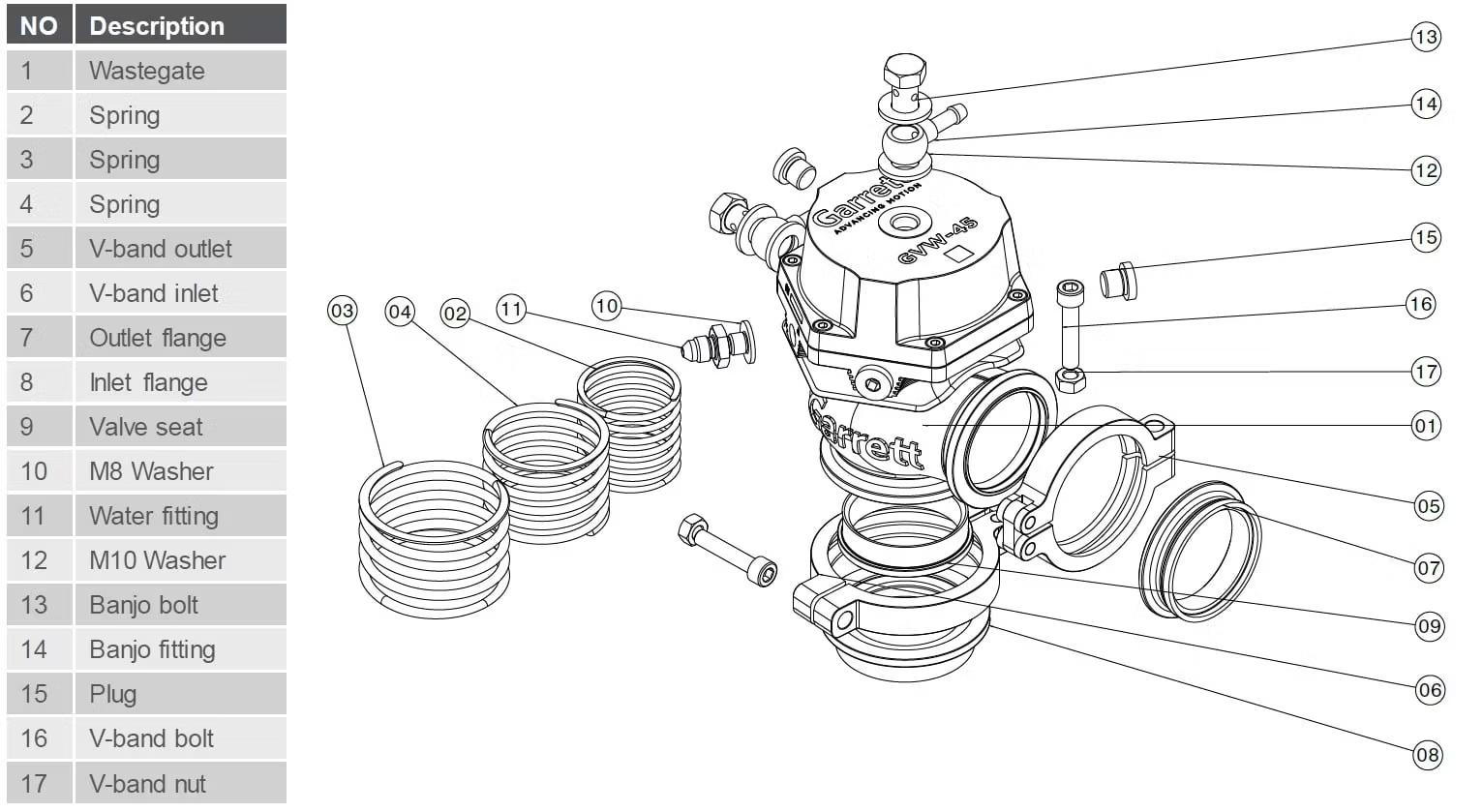

Kit Contents

GVW Wastegates include all the following parts:

- Springs

- V-Band: Inlet | Outlet

- Outlet Flange

- Inlet Flange

- Valve Seat

- Washers: M8 | M10

- Water Fittings

- Banjo Bolt and Banjo Fittings

- Air Plugs

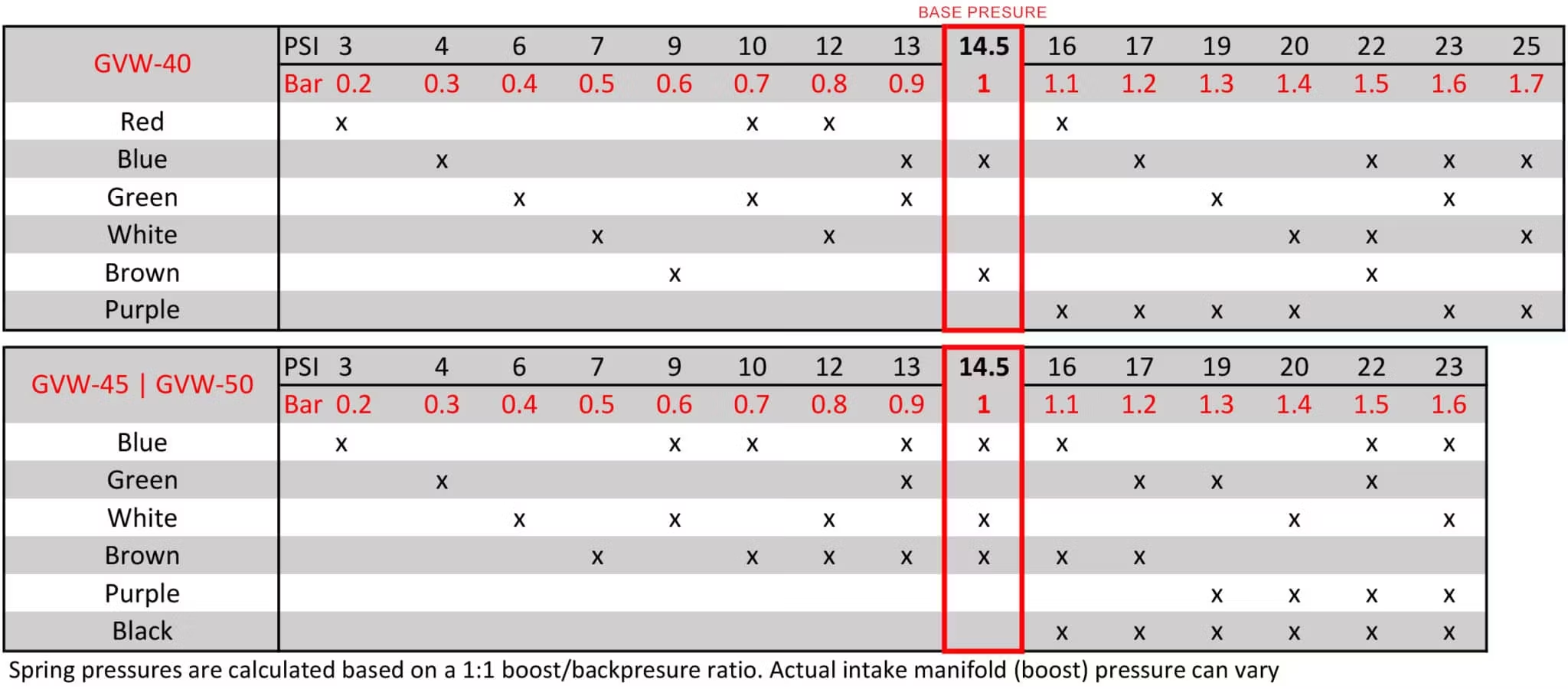

Wastegate Springs

GVW wastegates are set to 1 Bar | 14.5 PSI of base pressure and can be configured from 0.2 Bar | 2.9 PSI – 1.7 Bar | 24.7 PSI (considering 1:1 backpressure).

Use the chart to reference wastegate size and spring color to identify Garrett GVW wastegate spring pressures

Wastegate Flange Specs

GVW Wastegate flanges can be references in this data:

- GVW-40: Inlet OD 55.4mm | 2.18in Outlet OD 48.9mm | 1.93in (Interchangeable with Tial MV-S)

- GVW-45: Inlet OD 63.5mm | 2.50in Outlet OD 55.4mm | 2.18in (Interchangeable with Tial MV-R)

- GVW-50: Inlet OD 68.0mm | 2.68in Outlet OD 63.5mm | 2.50in (Interchangeable with Turbosmart Gen V ProGate 50)

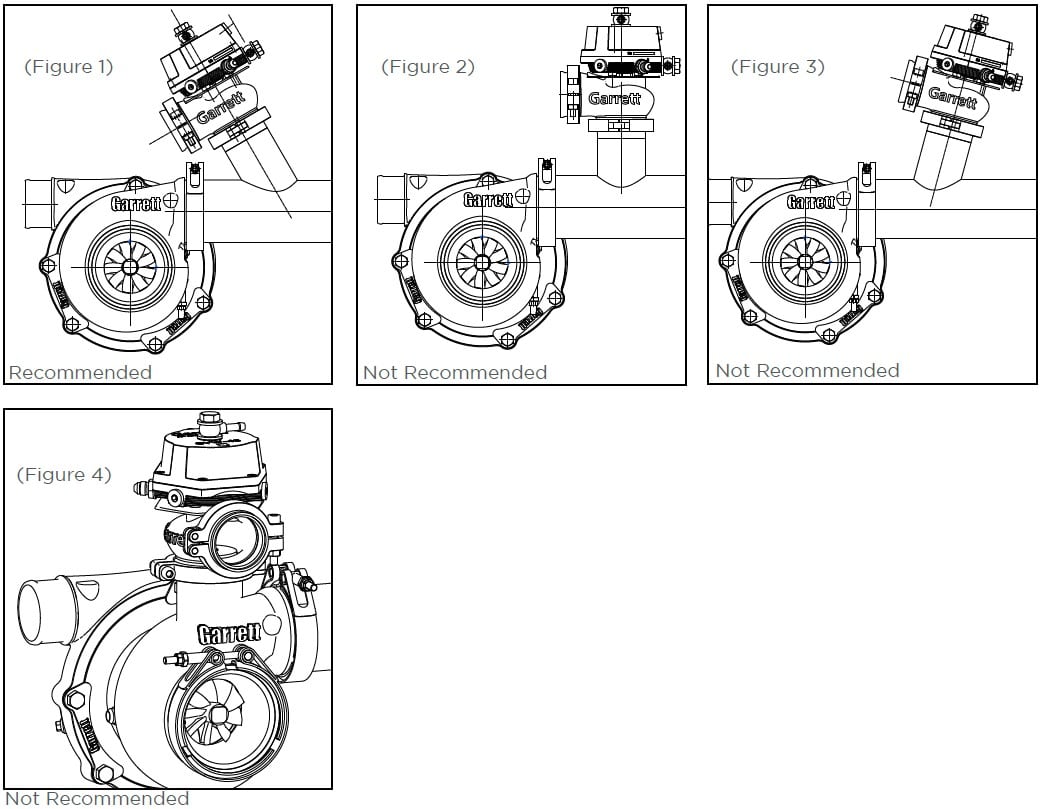

GVW Wastegate Placement Suggestions

Wastegate placement on the exhaust manifold is a key factor in wastegate performance. The following suggestions can help identify the best choice when purchasing or fabricating an exhaust manifold for your project. The connection on the manifold greatly affects flow capability, and correct orientation of the wastegate to the manifold is essential.

The ideal connection is at 45° with a smooth transition (Figure 1). Placing the wastegate at 90° to the manifold (Figure 2) will reduce flow capacity by up to 50 percent and can cause over boosting! More reduction in flow capacity will result if the wastegate is placed at angles greater than 90° (Figure3). Figures 2 and 3 greatly reduce the control you have over the system and can put your entire drive train at risk. Never mount the wastegate to the turbine housing at any time, this will reduce the performance of the turbocharger (Figure 4). Contact an authorized distributor for additional information.

Vi på Turboshop Sweden AB anser att detta är en oerhört fin och utvecklad wastegate & går direkt upp en nivå mot övriga wastegates på marknaden.

English

English

Dansk

Dansk